First Articles Fast

Rapid Prototyping Made Easy

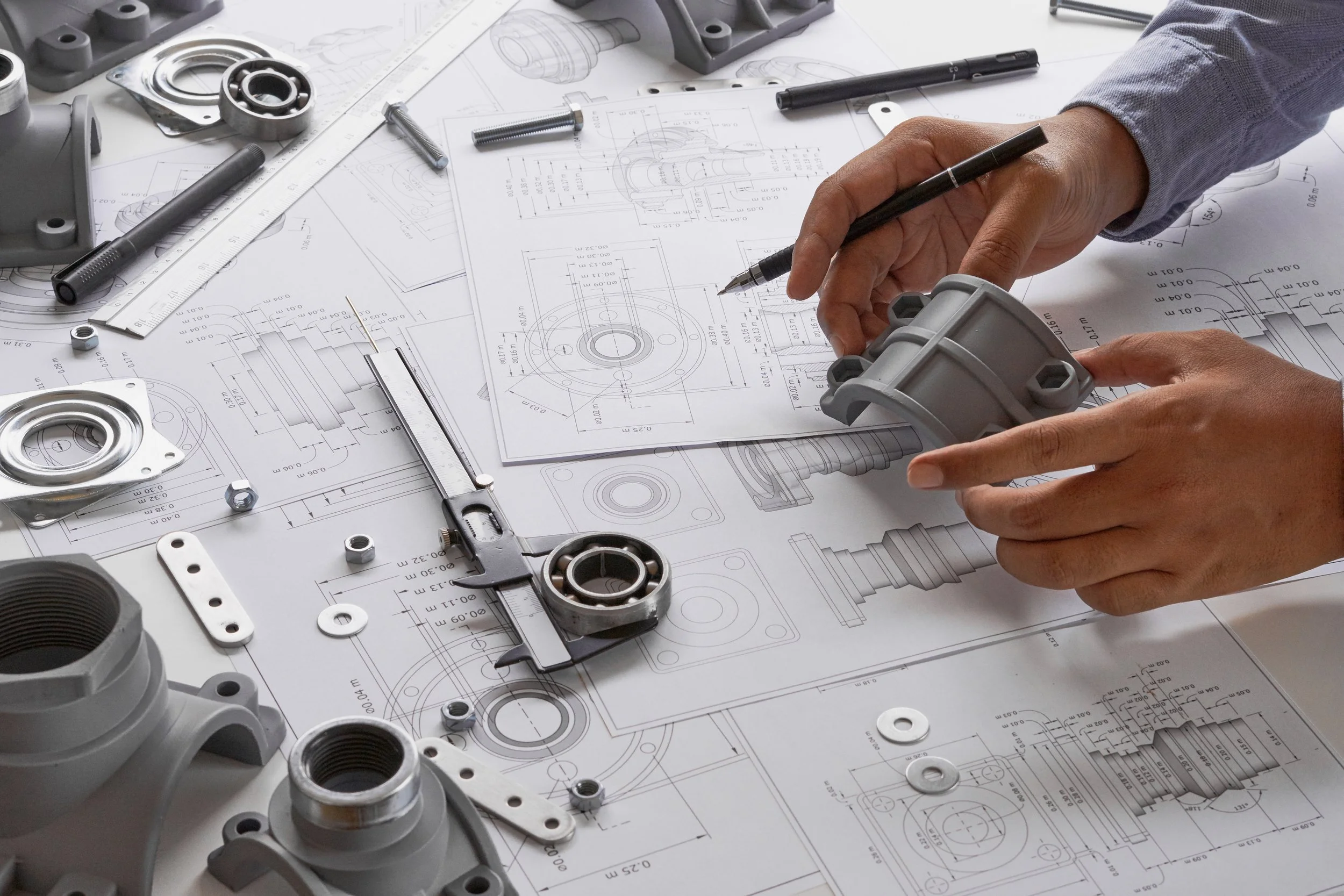

Wherever you are in the production process, IPC Foundry Group can get you from concept to cast parts in just a few weeks. Submit a 3D model or CAD file, mail us an existing part, or even send us a sketch, and our engineering team will work with you to seamlessly onboard and develop your project.

Get Started in 3 Easy Steps

01

Submit Your Project

Contact our team with details about your project. You can include full 3D models, mail us an existing part, or even submit a simple sketch. Our engineering team will work with you to select alloys, finishes, and other product details and optimize your part for our production workflow.

02

We Get to Work

With your design(s) in hand, we’ll get to work tooling and producing wax models of your 3D design for the investment casting process.

03

First Articles & Future Production

We deliver your first articles in as little as two weeks. From here, we’ll work with you as you test internally and with focus groups. Whether you need new iterations or are ready for an entire production run, IPC can quickly get you from concept to completed parts.

The IPC Advantage

All Your Metalworking Needs Under One Roof

From 3D modeling to finishing work, the IPC Foundry Group is your one-stop shop for all of your rapid prototyping and casting needs.

01 Two Domestic Foundries

We have modern foundries in Utah and Texas, offering 24/7 production cycles, large production volumes, and lightning-fast turnaround times. Connect with our domestic teams to get prototyping done fast. Visit the foundries in-person and take a hands-on approach to your product development.

02 International Partners

Looking for exotic materials for your prototype or complete project? IPC’s international partners offer access to aluminum and titanium and an expert team to take your project from concept to reality. Avoid off-hour meetings by communicating with our domestic team while enjoying all the perks of offshoring.

03 Finishing, Machining, and Testing

Whether you need a prototype for a new product or are updating an older one, The IPC Foundry Group has an array of finishing, machining, and testing partners for your prototyping project. Experiment with different finishes, paints, stampings, anodization, platings, and more. Once you’ve settled on a design, achieve certifications and comprehensive testing. Do it all with IPC!

Onshoring with IPC

US-Based Rapid Prototyping

The IPC Foundry Group strives to be a partner you can count on, offering prototyping and casting solutions for clients looking to bring their manufacturing back to the United States. Whether required by mandate - or if made in the USA is a staple of your business, IPC offers two modernized domestic foundries ready to take on your metalworking projects, big or small.

How it Works

Optimizing Every Step

From Solidworks on your desktop to completed prototypes in hand, IPC Foundry Group strives to be a partner that earns your business throughout the production cycle. We offer engineering and production services that operate 24/7, ensuring your product launch is a success. From minor tweaks on a 3D model to installing new casting equipment custom-tailored to your production needs, IPC is invested in you every step of the way. If you want to see our team in action, you can schedule a free tour of one of our facilities or view our process step by step by clicking one of the links below.