Investment Casting 101

Learn the Basics

of Investment Casting

Investment Casting is used to precisely and reliably reproduce metal parts and tools hundreds or thousands of times. Learn more about Investment Casting by scrolling through this page.

Want to learn more? Schedule a free foundry tour to see investment casting in action and get answers to all of your questions.

Common Casting Types

Competitive Metalworking Methods

Investment Casting is the most affordable and precise way to replicate metal parts in bulk. However, there are other common production methods used in metalworking. Here, we’ll explore these methods to see if Investment Casting is the right fit for you

Sand Casting

Like Investment Casting, Sand Casting also uses molds, but instead of wax, two-piece molds are created by compacting sand and clay. These molds are cheap to make and allow for very affordable, small production runs. Sand casting is the crudest of these methods, yielding less precise parts. This lack of precision often requires lots of finishing, which can significantly increase costs.

Bottom Line:

Sand Casting is ideal when creating smaller quantities of parts that aren’t complex in design.

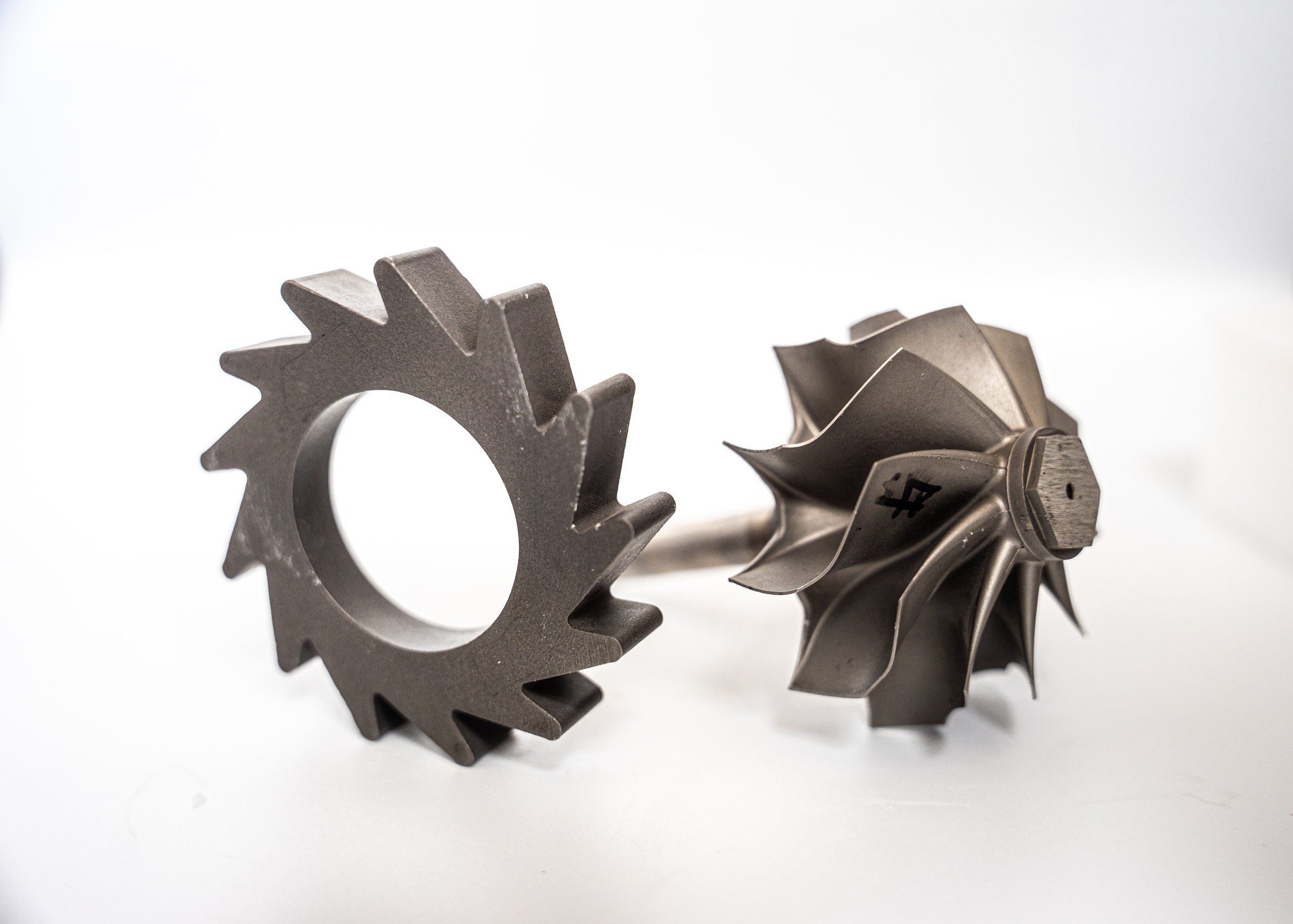

Investment Casting

Investment Casting uses wax models to create molds for metal parts. These small wax molds allow for very strong and intricate castings that can range in size from mere ounces to many pounds. These wax molds can be expensive upfront but will pay dividends when producing numerous parts. Some finishing/machining may be necessary for very complex designs, but there is no better method for manufacturing quality, affordable parts en masse.

Bottom Line:

Investment casting is the perfect fit for producing detailed metal parts in bulk.

Machining

Machining is a method where metal is shaped with precision tools. It allows for quick production and incredibly precise, detailed parts. However, this precision comes at a premium cost, and typically, machined parts aren’t as strong as their cast counterparts.

Bottom Line:

If you need small quantities of parts quickly, or when Investment Casting can’t fulfill complexity needs, machining is recommended.

How it Works

Investment Casting in 4 Steps

01

Making a Wax Pattern

Using state-of-the-art wax injection machines, We produce high-quality wax patterns of your part. Wax parts are clustered into “trees” so we can cast multiple components simultaneously.

02

Creating a Ceramic Shell

Wax trees are dipped into a ceramic slurry multiple times. Between dips, the slurry needs time to dry and solidify. The resulting ceramic shell makes the perfect mold for pouring metal.

03

Pouring Metal

The ceramic shells are superheated to melt the wax molds away. Your selected metal is then heated and poured into the hollow ceramic shells. The metal cools and your casting solidifies.

04

Finishing Touches

The ceramic shell is removed, and your casting is ground/sanded to meet your specifications. From here, your casting can be machine-finished, heat treated, painted, and more to get it ready for market.

All the Little Details

High-Quality Castings

Investment Casting allows for super-precise metal pouring with fine details at fractions of an inch. Check out just how precise we can be by downloading our tolerance table.

If you require even more precise details, our machining partners are some of the best in the industry; contact us for details!

Take Us For a Spin

Book a Free Foundry Tour

See the investment casting process firsthand and get all of your questions answered by our friendly staff. Schedule your free tour of our Texas or Utah foundry today!