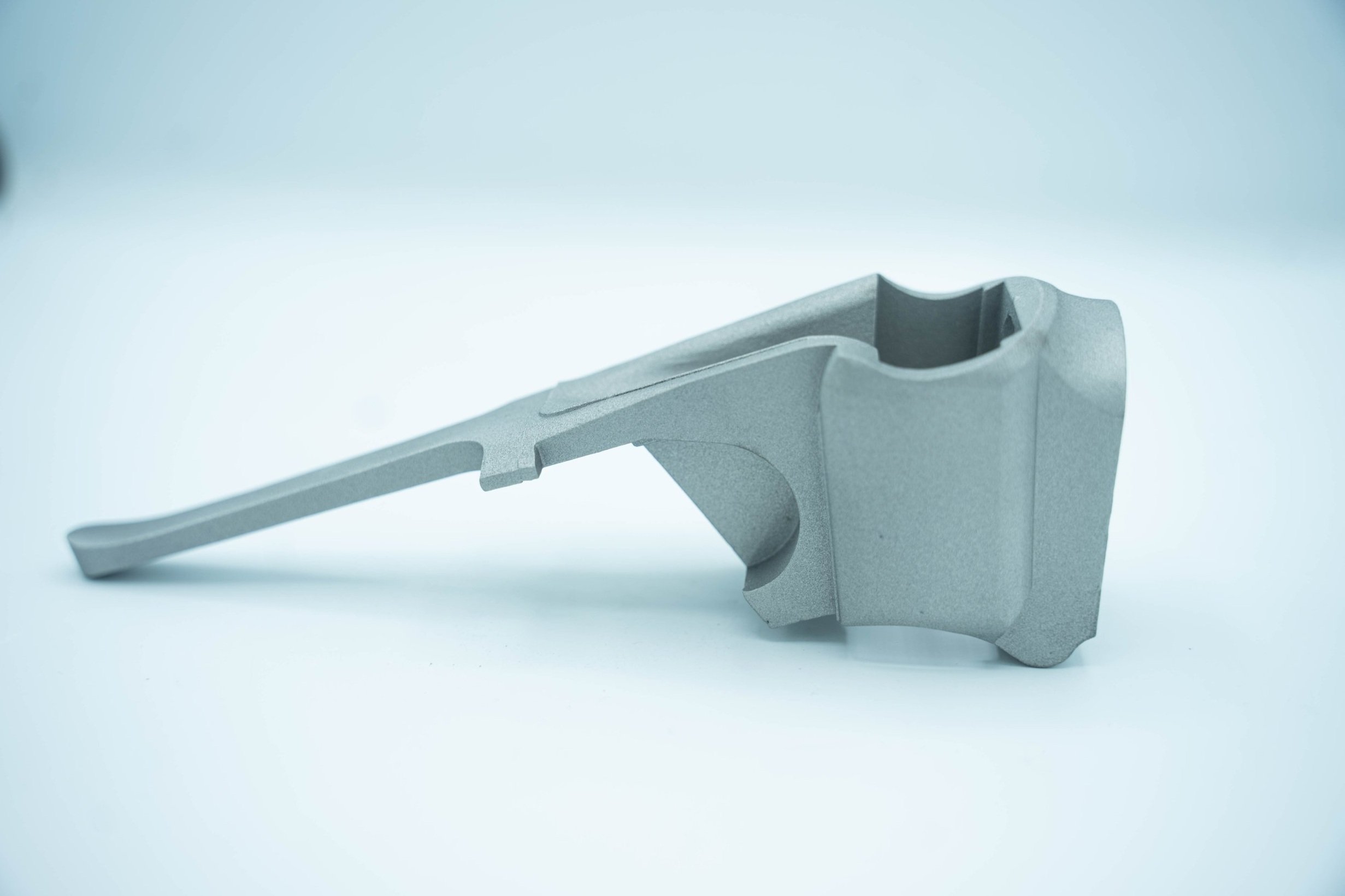

Cast Anything with IPC

Low Alloyed Steel

Investment Casting

IPC Foundry Group offers a wide selection of investment casting materials, including dozens of low—and medium-carbon steel alloys. These do-it-all materials offer good hardenability, strength, wear resistance, toughness, and ductility - with additional flexibility afforded by heat treatment options that allow them to attain a range of toughness and strength values. As a bonus, they are some of the most economical alloys on the market!

Kick off your next casting project with IPC. Our over 45 years of expertise can get you to market faster than ever with exceptional metal parts.

Casting 101

A Quick Look at

Low Alloyed Steels

Widely used across hundreds of industries, low- and medium-carbon steel alloys are an economical and design-friendly material option that offer a combination of strength, ductility, and hardenability, especially when coupled with secondary coldwork or heat-treating operations.

-

Low-alloyed steels are a go-to choice for many structural components, including automotive applications, bridges and buildings, construction materials, mining/ground equipment, and more. Low alloyed steels are also frequently used in the agriculture and oil & gas industries.

-

Low Cost

High Strength

Good Hardness

Good Wear Resistance

Design Flexibility

Good Ductility

Can be heat treated with different methods to achieve different tensile, yield, elongation, and hardnesses with the same base as-cast chemical composition

Good Weldability

-

Low and medium-carbon steels are cheaper than their stainless steel counterparts. In applications where corrosion and heat resistance aren’t as important, you can get excellent strength components that are much more affordable than high-alloyed steels.

-

Following the casting process, heat treating can increase tensile, yield, elongation, and hardness while maintaining the as-cast chemical composition.

Workhorse Alloys

Low and Medium-Carbon Steel Precision Casting

With hundreds of material options to choose from, you can cast anything with IPC. In the section below, we've listed our most commonly poured low-carbon and medium-carbon steel options. If you're looking for something different, no worries! We pour virtually every air-melt alloy and offer a selection of vacuum-melt alloys, such as aluminum and titanium, through our international partner foundries.

If you have questions about our material options or any of our services, contact our team today!

Low Carbon Steels

Strong, low-cost, and weldable, this class of alloys is ubiquitous and seen in anything from military applications to consumer goods.

Common Usage Scenarios:

Construction components, bridges, structural components, home goods, gears, cogs, automotive applications.

Most Common Pours at IPC

1020 Steel

4320 Steel

8620 Steel

25CrMo4

Medium Carbon Steels

Strike a good balance of benefits between low-carbon steels and higher-alloyed options (like stainless steel). Materials like the ever-popular 4140 steel can withstand wear and tear while offering good hardenability, ductility, wear resistance, and heat-treating options.

Common Usage Scenarios:

Sprockets, gears, structural components, shafts, bearings, joints, axels, automotive components, mining components, mining equipment

Most Common Pours at IPC

1030 Steel

1050 Steel

4130 Steel

4140 Steel

4340 Steel

Your Precision Casting Partner

Why Choose IPC?

Whether you have a time-tested part or are still in the product development stage, IPC is a casting partner you can count on every step of the way.

01

50 Years of Casting Experience

We have a rock-solid reputation for producing quality parts and providing next-level customer service. Throughout our history, we've offered low- and medium-carbon steel castings to thousands of clients across dozens of industries, including petrochemical, oil and gas, agricultural, infrastructure, and many more.

02

Scalable Casting Solutions

Have variable production needs or a unique manufacturing challenge? Look no further! At IPC Foundry Group, we invest alongside our clients to provide a partner and service you can count on for years to come.

03

24/7 Production Cycle

Utilizing our two domestic foundries and top-of-the-line automated investment casting equipment, your production cycle happens 24/7, 365. Count on shorter lead times, competitive pricing, and expertly cast parts.

04

Offshoring Made Easy

Interested in offshoring your production? IPC has international partners standing by, enabling you to offshore your components while maintaining communication with our domestic team. No off-hour meetings, no language barrier, just hassle-free precision cast parts.

05

All of Your Metalworking Needs in One Place

We are a one-stop shop for all your investment casting needs, from prototyping and production to machining, testing, certification, and shipping. Save time, money, and headaches by doing it all with IPC.

Onshoring Made Easy

US Based Casting Foundries

IPC is a trusted onshoring partner. We specialize in helping companies bring their production back to the US without hassle and without skipping a beat.

We offer scalable casting solutions and 24/7 production cycles to tackle your project regardless of scale.

-

40K sqft production space

3 x 300# and 1 x 50# melt pots.

Max ideal product size – 50# and 24” cubed.

Typical lead time 6-8 weeks

-

30K sqft production space

2 x 300# and 2 x 50# melt pots.

Max ideal product size – 40# and 18” cubed.

Typical lead time: 6-8 weeks

Foundry FAQs

Is Investment Casting

Right For You?

Investment casting is best suited for medium—and large-scale production volumes or projects with complex geometries unobtainable from alternative casting methods. If you are looking to produce a smaller volume of parts, machining, sand casting, or another method may be a better fit!

Want to learn more about the pros and cons of investment casting? Check out our Casting 101 page, or use the link below to follow the investment casting process from start to finish.

Quotes done Quick

Get a Quote

Send us a few project particulars and get a custom quote in as little as 24 hours. Have questions for our team? We’d love to help! Use the link below to get in touch.